Product Description

The 150 Booklet System combines the DBM-150/T Bookletmaker and Trimmer into an efficient, all-in-one solution that integrates stapling, folding, and face trimming. This eliminates the need for separate Collating, folding, stapling and trimming, streamlining production.

The DSC-10/60i Collator provides the flexibility to feed output from multiple presses, whether offset or digital, allowing users to reduce job costs and complete projects quickly. With the ability to produce up to 2,400 booklets per hour, this system is ideal for handling a variety of offset and digitally printed applications, including catalogs, manuals, newsletters, and marketing materials. Efficiency and Ease of Use

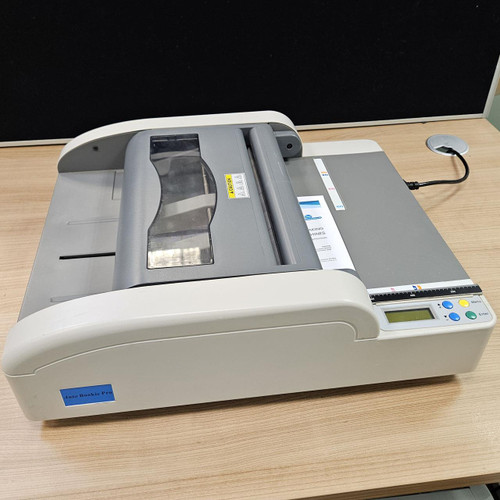

The DBM-150 Bookletmaker features an intuitive LCD control panel that simplifies job programming and fine-tune adjustments. Operators can quickly select or enter custom paper sizes, and the machine will automatically adjust staple, fold, and trim settings. The system also allows for quick changeovers between different job sizes, with minimal operator intervention and tooling required. Up to 16 jobs can be saved and recalled at any time, improving efficiency for repeat work. Collating with the DSC-10/60i Designed for reliability, the DSC-10/60i Collator enhances booklet production by handling output from multiple presses and finishing jobs faster than in-line systems.

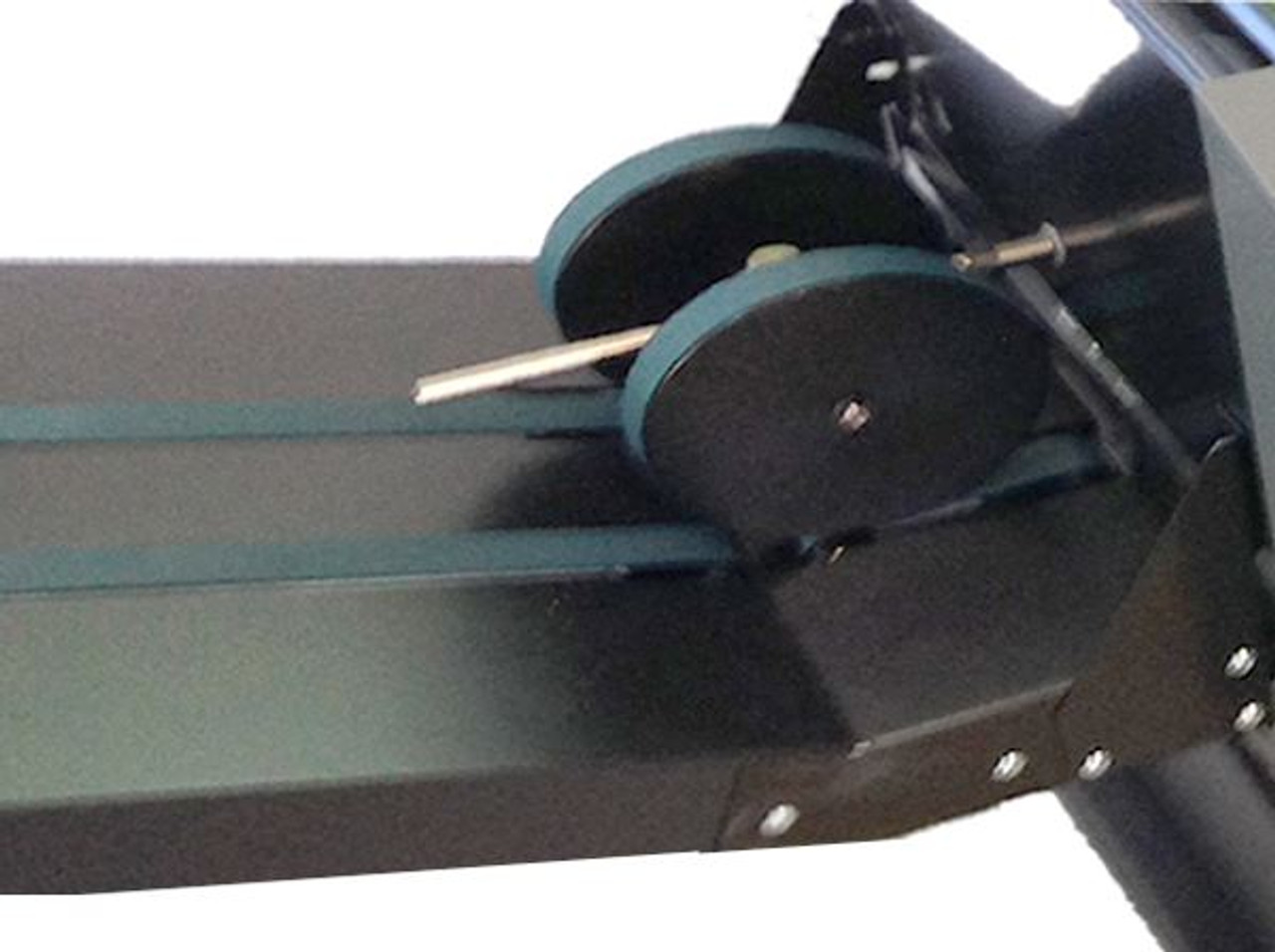

The DSC-10/60i is equipped with Duplo’s air suction belt feeder and air management system, this high-performance collator ensures consistent separation and feeding. Each of its 10 bins features dual fan technology, allowing for fine adjustments and a steady flow of air. The machine detects loaded bins automatically, while high-resolution sensors monitor for misfeeds and double feeds. Any faulty sets are diverted into a reject tray, which can then be reinserted manually using the hand-marry station. When a bin is empty, the system automatically switches to the next programmed tower for uninterrupted production.

The DSC-10/60i is an opinion another collator option is the friction collator DFC-102

Precision Bookletmaking for a Professional Finish The DBM-150/T automates booklet production, minimizing downtime and increasing productivity. Each set is collated, jogged into alignment, and seamlessly guided through the stapling, folding, and trimming process. The system performs saddle stitching, corner stapling, and side stapling of up to 25 sheets, ensuring professional results across a variety of booklet formats.

Booklets are finished with a clean fore-edge trim for a polished, high-quality look. Operators can also manually feed collated sets directly into the bookletmaker, without requiring additional kits. Staple cartridges are easy to replace, further streamlining the workflow.

Options for Enhanced Performance. To further expand capabilities, the 150 Booklet System can be upgraded with:

- DSS-350 Square Back Unit for square spine booklets.

- Additional DSC Collators to increase feeding capacity.

- DBM-4000STR Deep Pile Stacker for enhanced output handling.

- Collator options: DSC-10/60i air-fed collator or DFC-102 Friction collator

- Control Panel for DSC-10/60i

With its automated job setup, advanced collating technology, and precision booklet finishing, the 150 Booklet System is the ideal solution for businesses seeking to streamline production and improve turnaround times while maintaining high-quality results.

| Max Sheets | Produces booklets with saddle or corner/side stapling up to 25 sheets |

| Operation: | Automatic - Saddle Staple |

| Adjustable: | Yes |

| Speed: | Up to 2,400 sets per hour (10 sheets 80 gsm LTR) |

| Paper Size: | 120 mm x 210 mm - 320 mm x 460 mm |

| Dimensions W x D x H (mm) | 745 x 780 x 1708 |

PRODUCT VIDEO

British Pounds

British Pounds

Euro

Euro