Paper Folding Machine Buying Guide

Paper Folding Machine Buying Guide

Please see below our UK guide to buying a paper folding machine. This has been compiled by our experienced staff to help you purchase the correct letter folder for your application. Should you need any further advice please don't hesitate to contact us. We are a technician driven company and are happy help. See the range of paper folding machines.

Paper Size: This tends to be an easy decision. If you only fold A4 paper, then every paper folding machine is suitable on that basis. Any A3 paper folding machine will be able to fold A4 paper too in a variety of ways.

Productivity: Please make sure that you choose a paper folding machine that is suitable for the work you are doing. Our adverts state a "designed for / recommended usage", so make sure you keep these in mind. The most common difficulty paper folding machine customers have is that they have purchased a machine that is too small for their requirements.

Volumes: Please make sure that you choose a paper folding machine that is suitable for the work you are doing. Our adverts state a "designed for / recommended usage", so make sure you keep these in mind. The most common difficulty paper folding machine customers have is that they have purchased a machine that is too small for the volumes that they wish to fold.

Paper Thickness / Coating: Please make sure you select a machine that can handle the weight of paper that you're using. Paper weights quoted are based on non-coated paper, so if you're using glossy or coated paper firstly make sure you select a paper folder with speed control. Also reduce the advertised thickness by 30gsm for a light coating or 50gsm for a heavy coating. If in doubt, please contact us. We are more than happy to do test runs for you if you would like to send us samples of the paper you wish to use.

Number of Feed Tyres (not applicable to high end, air feed paper folding machines): These are like the tyres/wheels on a printer, but in the instance of a folding machine, the paper has already been processed. As paper is pulled into the machine it resists being pulled and tries to twist (screw). The more feeder tyres that there are and the wider they are the better. These are the tyres that initially pull the paper into the machine. This helps the initial pickup of the paper as well as stopping the paper twisting, which can cause a variety of problems.

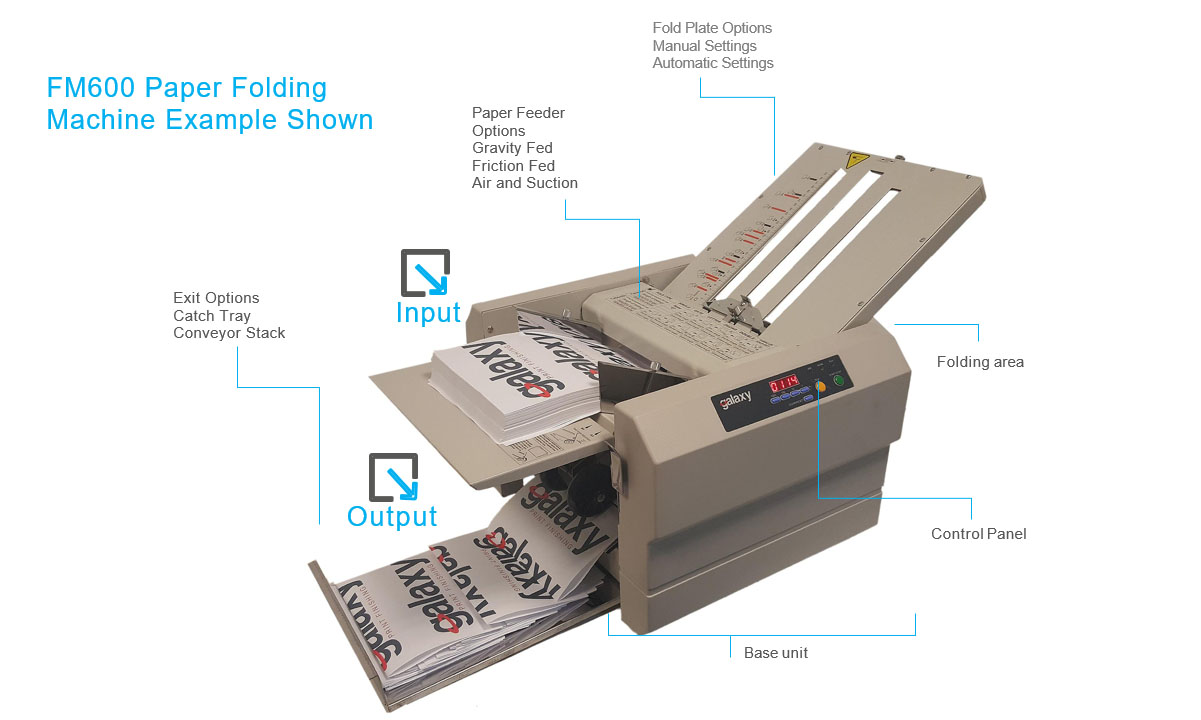

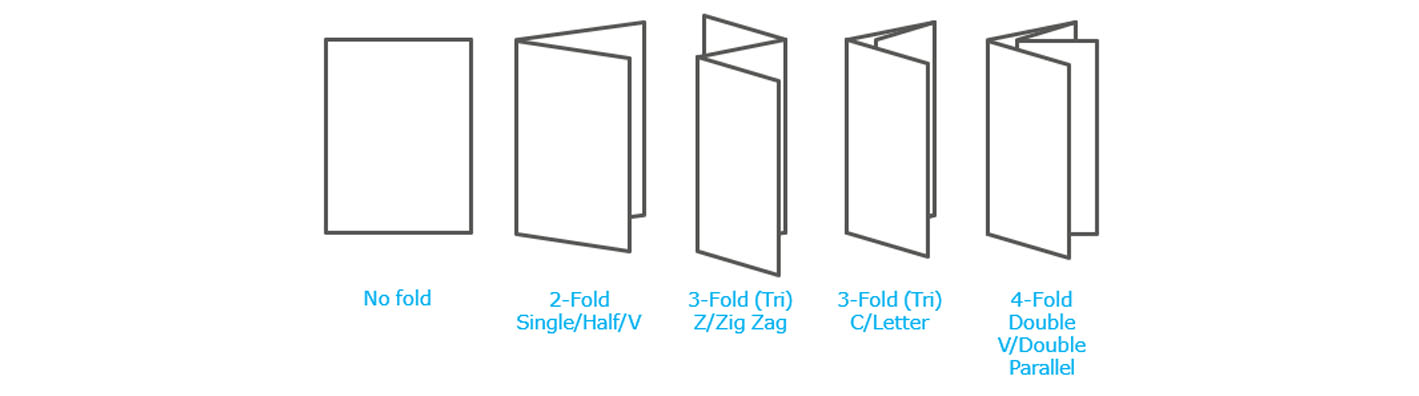

Fold types: Please make sure that you choose a paper folding machine that will be able to do the type of fold you require. Our adverts show pictures of the fold type that a model can do, making this one of the easiest choices when buying your letter folding machine.

Sheets Per Hour / Per Minute: This is the maximum speed at which the letter folding machine will run paper through. This figure is based on the paper folding machine industry standard of 70gsm paper, folded into 3 for a DL size envelope. These figures do not consider any downtime such as the reloading the paper feeder.

Presets: Regular jobs can easily be preset on your folder inserter to save time when changing applications. Presets are easy to assign, although your first presets will be set up by the installing engineer when your machine is installed.

Feed Tray Capacity Hopper: The number of sheets of flat 70gsm paper the paper folding machine will hold in its paper feed tray (also known as a hopper).

Automatic / Manual: An automatic paper folding machine pulls sheets of paper from the feed tray, one after the other "automatically". All but the smallest hand-fed paper folders feed "automatically".

Cross fold: This is a process where paper is folded twice, NOT in the same direction. For example, A3 down to A4, then across to A5 size. Only a limited number of machines can produce this type of fold and doing so can limit the options on paper you use. Feel free to consult with us as to your cross-fold needs and potential solutions.

Multiple Sheets Hand-feed Only: This is also known as a manual bypass. Some paper folding machines allow the operator to insert stapled and non-stapled sets of paper into the folding machine paper feeder by hand. Please note that the smallest folding machine capable of this is the Martin Yale 7200. However, the manual bypass on this letter folder does not have a side guide which can create regular "skewing" of the paper. If a quality manual bypass facility is important to your application, we recommend looking at machines from the Martin Yale 1611 upwards.

Auto Detect and Stop: Simply put, this means the paper folding machine "knows" when there's paper in the hopper. The machine will detect that the paper has run out and automatically stop.

Extended Warranty: Ongoing warranty and maintenance cover is available on selected paper folding machines.

Preparation for Paper Folding - Hints and Tips: All paper folding machines supplied by Postroom-online come with our guide to paper handling, as well as the usual manufacturer instruction manual. But here are a few of the key things to note.

Heat: Many printers use heat to transmit text, pictures etc. to the surface of the paper. Heat causes paper to distort and curl so if the paper is then loaded immediately into the print finishing machine, in this case a paper folding machine, this will cause problems. A simple way to resolve this is to lay the paper on a flat surface until it has cooled down. As the paper cools it will regain some of its original shape. It's then easier for the paper folding machine to handle the paper. One way to speed up this process is to lay a heavy object on top of the stack e.g. a telephone directory.

Static electricity in the paper: Some printers cause static electricity to build up on the paper service. This will cause paper to stick together when trying to pass through the separator roller on the paper folding machine. This can cause paper jams and double feeds to occur. A simple way to resolve this is to again, lay the paper on a flat surface (even better on a metal surface) for a while. This will help the static electricity to discharge, which makes it easier to induce air between the sheets to help the machine perform correctly. Good paper handling makes good sense. To get the best out of your machine it's wise to follow these steps.

Paper Joggers and Air Joggers: The preferred choice of the print finishing industry, print shops and mailing houses, these machines eliminate electrical static and heat as well as ink and toner residue in seconds. They greatly improve feeding performance of paper folding machines, folder inserters, creasing machines and other rubber-roller-fed print finishing processes. Prices have dramatically fallen in recent times, especially on higher end air joggers, making these professional machines suitable for in-house applications.

Roller Rejuvenator (Roller Cleaner): Roller rejuvenator cleans off paper dust, which can cause rubber rollers to slip on paper resulting in unintended creasing. It rejuvenates the rubber on the rollers keeping it soft and grippy. This improves both the performance and life of the roller.

Quality Advice: Speak to a specialist straight away on our freephone telephone number 0800 0432 758

British Pounds

British Pounds

Euro

Euro